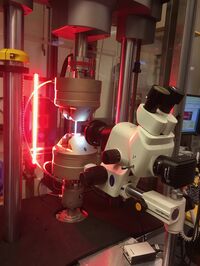

Mechanical testing

Linear-Torsion (biaxial) All-Electric Instrument for Static and Dynamic (fatigue) Mechanical Testing

Instrument Specification

- Bi-axial load:

- 10 kN linear (dynamic), or

- 7,5 kN linear (static), and

- 100 Nm torque,

- in any combination;

- Stroke:

- 60 mm (+/- 30 mm) linear; and

- up to 135° (or +/-16 revolutions) torsion

- Magnification (FOV):

~2x (ø105 mm) – ~35x (ø6.5 mm)

Possibility to record video-signal alongside stress-strain data with full time synchronization within the same software environment for a following analysis with digital image correlation (DIC)

Linear Electro-Mechanical Instrument for Static Mechanical Testing

Instrument Specification

- Instrument type: Table-top;

- Uni-axial load: up to 10 kN linear (static);

configured to work in a range of 1 - 2'000 N at present. - Crosshead Stroke: up to 760 mm (+/- 30 mm) linear;

- Displacement Speed Range: 0.001 - 1000 mm/min;

- Data Sampling Rate: 1000Hz max

Acoustic Emission (AE) measurement system

This is an auxiliary fully mobile system for the in situ monitoring of various events (deformation mechanisms such as twinning and dislocation slip, fracture, etc) during mechanical testing. It can be linked to the Instron E10000 instrument using two analogue channels allowing perfect time synchronisation of stress-strain data with events generating generating acoustic signal.

Location: room M:2383

Creep testing machine custom-built by Phoenix Calibration

Micro Materials NanoTest Vantage

Nanoindentation system.

Available through the Department of Mechanical Engineering for shared use.

Location: room M:mechanical workshop